Food processors are arguably dealing with more challenges than ever before: an exacerbated labor shortage and heightened attention to sanitation practices following the COVID-19 pandemic. Water scarcities. Tightening government regulations. New sustainability initiatives. Add chemical and water waste to the mix, and the challenges become even more costly.

Fortunately, there are several measures you can take to gain control of your processes and get ahead of these issues. Designed for consistent and controlled chemical mixing and dispensing, Birko’s Blend OnSite Solutions may be the answer to some of your chemical and water challenges. Here are a few ways the Blend OnSite Solutions can help.

Manage and Control Chemical Dispensing—and Protect Your Workers

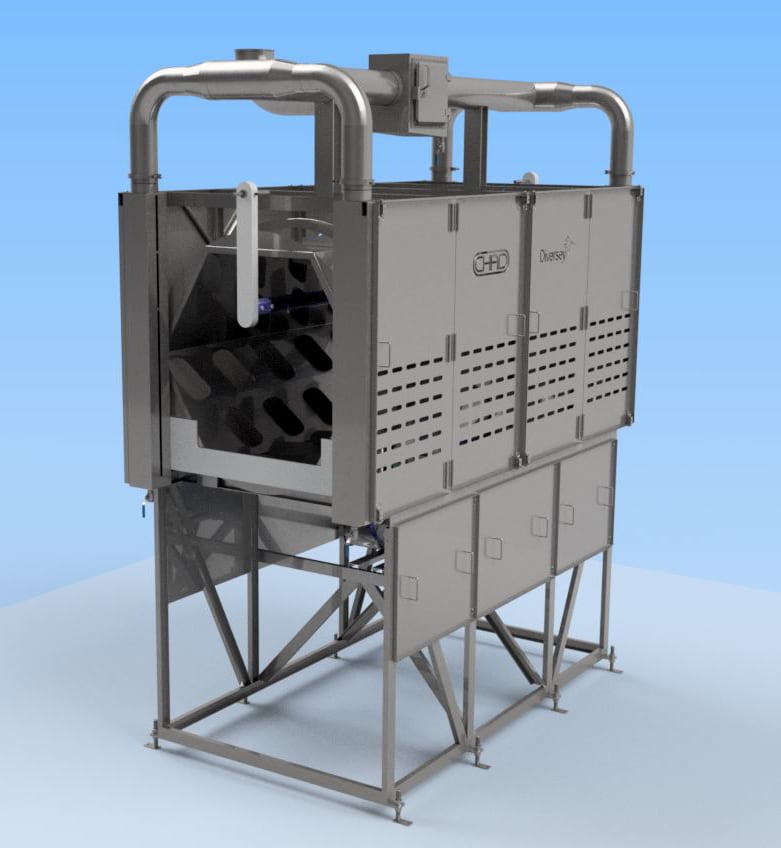

Birko’s Blend OnSite Solutions is a suite of chemical dispensing controllers for companies that are looking for a better way to manage & control chemical dispensing. Custom configured controllers to either chemical dispense only or blending precursor chemicals to provide a tailormade chemical solution. This minimizes the possible human error when mixing chemicals by hand and reduces chemical waste. Improper chemical concentrations can cause damage to equipment, result in product recalls or injure workers. According to OSHA, chemicals are one of the top hazards in workplaces, particularly in meat processing plants. BOSS systems can be instrumental in preventing incidents like these, giving plants a safer, more reliable solution for accurately dosing chemicals and eliminating the need to carry them.

Birko’s chemical dispensing controllers help users to better manage, and control dispense usage.

Blend Chemicals OnSite to Save Labor and Resources

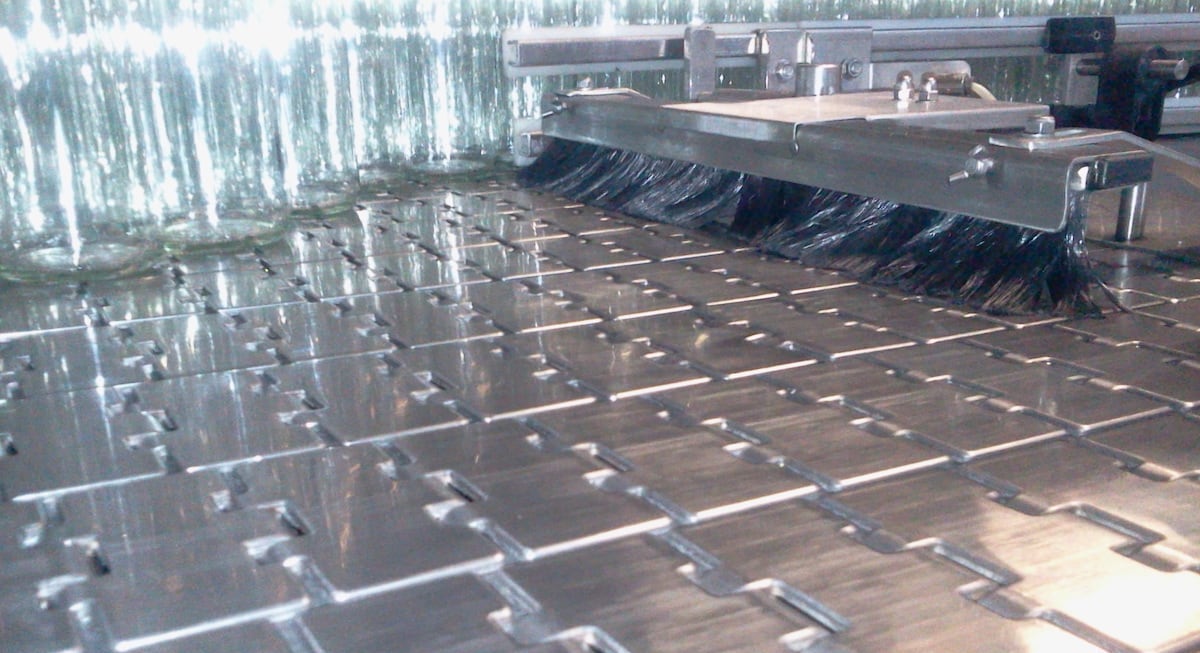

Another significant benefit of the Blend OnSite Solutions is onsite blending capability, meaning fewer drums and totes to handle and dispose of. By switching from dispensing only to blending chemicals, the processing facility will conserve space while saving in shipping costs. This is because pre-mixed chemicals already contain 30-40% water. Since workers don’t have to spend as much time hand mixing chemicals before the sanitation process shift, BOSS systems can help facilities save time and labor. BOSS systems can also be paired with Birko by Lagafors® sanitation system to further improve cleaning ability.

“Water is becoming scarce throughout the United States right now. Lake Mead, outside of Las Vegas supplies water to 25 million people, is at its lowest level on record. The Ogallala Aquifer, one of world’s largest underground water supply, is depleting at a rate of 12.3 million gallons per day, and it’s generally getting more and more difficult to access water. The Birko Blend OnSite Systems give food processors the ability to track how much water they’re putting into the system each night and holds workers more accountable for how much they’re using. – Parker Staats [Birko Equipment Sales]

Want to learn about saving labor, water and utilities in food processing? Read our free, exclusive e-book on solutions to today’s food processing challenges.

Blend OnSite Models for Sanitation Chemical Mixing and Dispensing

Birko offers three suites of sanitation systems with varying levels of features to meet your unique needs. These suites are compatible with Birko sanitation chemicals for several applications, from beef processing to brewing and distilling.

The Birko Lite model is an economical, entry-level system that restricts access to chemicals to only authorized users and records all chemical use data in a downloadable format. Administrators have the option of adding RFID card readers or using login codes.

The Birko Elite model is a mid-level chemical dispensing solution with similar features to the Pro, such as RFID card access, dispensing reports and the ability to limit access to chemistry between users. It records who has accessed chemicals, the amount of solution and how often, and administrators can connect to it via WiFi in the facility.

The Birko Pro model provides sanitation managers the highest level of control, recording and reporting. The Birko Pro allows for weight-based dispenses and is accessible remotely, allowing managers easy access to data from multiple facilities. The Pro model can send automated email alerts to account managers, plant personnel and chemical operators. It enables administrators to restrict access to recipes to specific users, creating greater control over restricted products.

The Birko Pro model utilizes the Clean Intel reporting system, giving the sanitation managers the ability to see real-time chemical usages from their desk, via the web-based system. Clean Intel also has the ability to view multiple facilities for corporate sanitation.

Custom Sanitation Systems for Food Processors, Brewers and Distillers

Birko’s Blend OnSite Solutions are tailormade to fit your specific needs based on your facilities, chemistries, budget and other factors. We’ll work with you to identify which model and chemistries will result in the greatest ROI and best help you gain control over your chemistry and water usage.

“The Birko Blend OnSite suite of systems give the sanitation manager tools to control the chemical mixing & dispensing while improving employee safety.” – Parker Staats

Talk with one of our chemistry and equipment experts today about your sanitation situation and needs. As an integrated sanitation, chemistry and equipment provider with three generations of experience, we pride ourselves on being your partner in food safety. We’ll work with you to find a solution to help you reduce costs, liability and risk, ultimately protecting your business—and the food chain.