With much of the meat and poultry processing industry requiring significant resources to operate, being efficient with time, water, and chemical use is crucial. Fortunately, Diversey is committed to helping processors increase throughput while developing solutions that help balance their need for water, chemicals, and energy with their sustainability and food safety goals. By continually investing in research and development, our team has created a system that applies antimicrobial agents with greater precision, exceeding the performance of traditional dip or in-line spray systems.

Developed in partnership with Colorado State University, the Elite 360® system is empowering meat and poultry processors by successfully eliminating pathogens, achieving significant water and chemical savings, and containing overspray to promote a safer working environment. The enhanced antimicrobial efficacy not only protects your brand but safeguards customers, while reducing the risk of a recall.

How the Elite 360® System Works

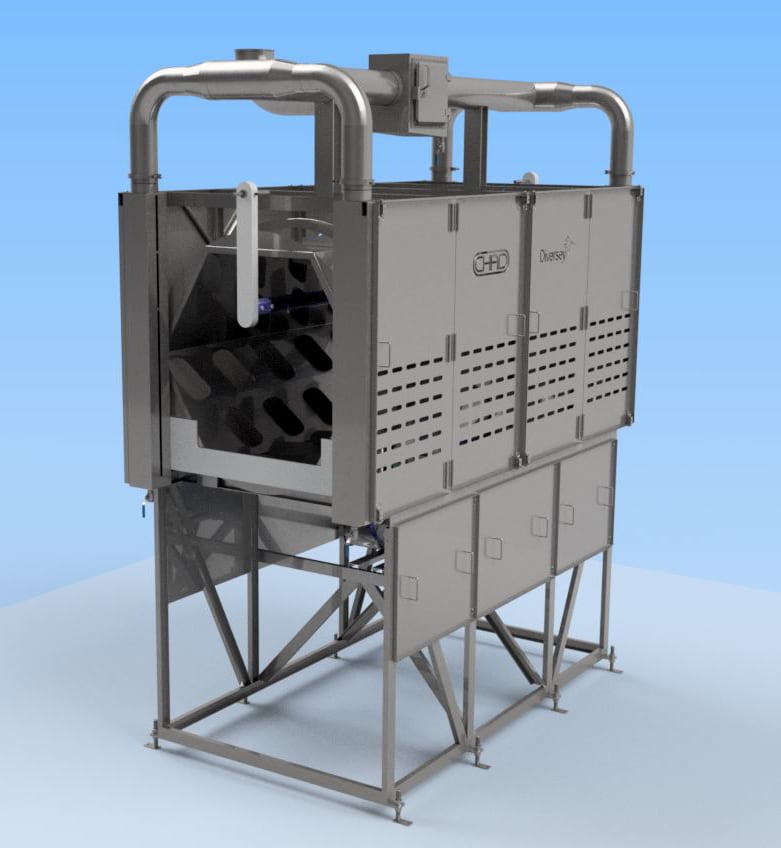

The Elite 360® utilizes the power of electrostatic spraying technology and leading-edge equipment to improve the transfer efficiency of antimicrobial interventions. Electrostatic spraying involves applying an electrostatic charge to the antimicrobial agents, causing an attractive force between the positive charge of the spray droplets and the negative charge of the meat’s surface. This attractive force allows the disinfecting intervention chemistries to wrap around the target, resulting in 100% coverage.

But electrostatic technology is often not enough on its own. The enclosed body of the Elite 360® further aids in the effective application of antimicrobial interventions by slowly rotating the meat products as they move along the production line. This gradual rotation helps to expose all surfaces of the product, resulting in an even distribution of the antimicrobial agent. Constructed to withstand the rigors of daily use, in-plant studies have demonstrated a consistent 2.5 log of E. coli reduction while treating up to 750 lbs. of beef trim per minute.

Reducing Resource Use

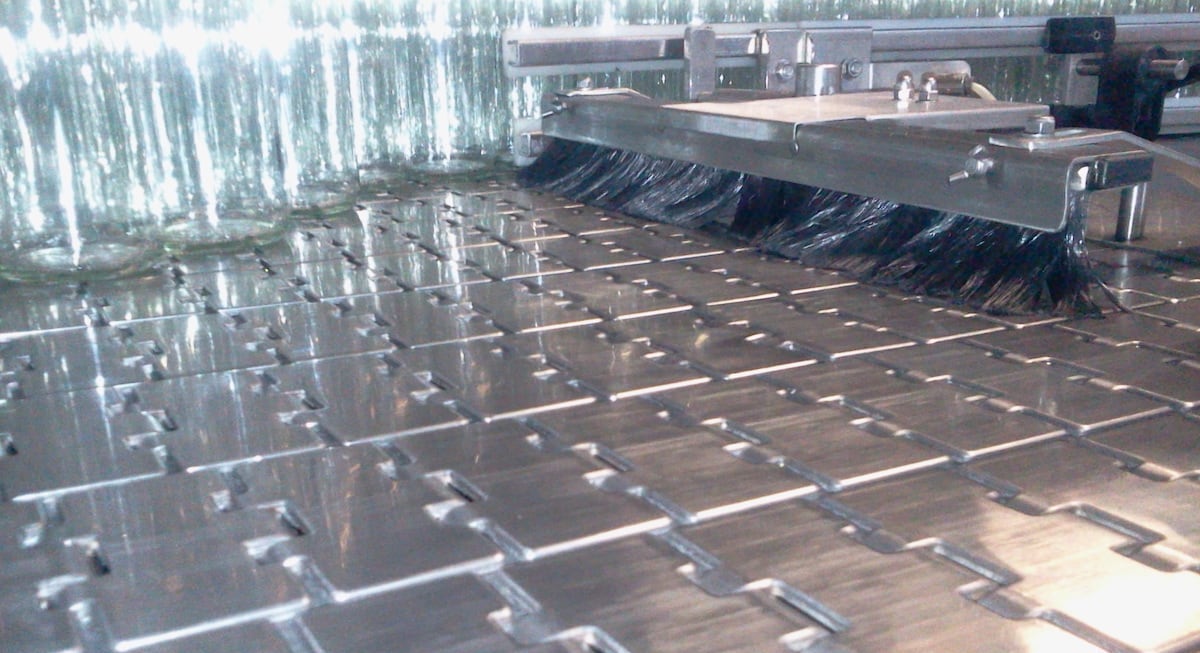

The process of applying antimicrobial agents has traditionally relied on dip or in-line spray systems. A traditional dip system involves immersing the meat and poultry products in an antimicrobial solution for a specific length of time. While this method can result in high transfer efficiency, it also requires high volumes of water and chemicals that need to be regularly replaced, resulting in significant waste. With an in-line spray system, processors can conserve resources, but they may be less effective in achieving the same full coverage that immersive dips provide.

The Elite 360® system not only achieves up to 100% transfer efficiency, but the innovative technology also requires significantly less water and chemicals compared to that of traditional intervention systems. Designed for precision, processors that have implemented the Elite 360® have seen a minimum of 70% reduction in the quantity of water and chemicals consumed during operation.

Addressing Overspray

Another serious challenge regularly associated with traditional in-line spray systems is overspray. Without an attractive force pulling the antimicrobial agent to the meat’s surface, traditional in-line spray systems often have a higher chance of missing the target area, causing the antimicrobial agent to circulate into the production environment. This issue further contributes to waste and poses a risk to worker safety. With Elite 360®, meat processors can virtually eliminate overspray.

While the electrostatic technology helps mitigate the chance of airborne droplets dispersing into the surrounding area, the enclosed chamber of Elite 360® assists by keeping the mist contained as product is actively treated. Furthermore, Elite 360® features an integrated exhaust system that functions to safely ventilate the structure. With this innovative technology, processors can feel confident that they are taking the steps necessary to reduce waste and promote worker safety.

The Elite 360® in Action: Pathogen Reduction for Ground Beef

One ground beef processor that utilized the Elite 360® electrostatic system for intervention on whole muscle cuts found it highly effective at reducing the microbial load.

Subprimal pieces were treated at a concentration of 1450 ppm using the Elite 360® system. The processor swabbed 20 subprimal pieces prior to treatment, exposed the meat to the solution for 20 seconds, and then 20 pieces were swabbed post treatment. The processor found that the 3.63 log pretreatment was reduced by up to 2.48 log post-treatment.

This case highlights the power behind the Elite 360® system and its ability to effectively reduce E. coli in beef products—helping protect the public from lethal outbreaks.

The Future of Intervention Technologies

To safeguard consumers from foodborne illnesses often associated with beef products, antimicrobial intervention application to cuts and trim prior to grinding has become standard practice. The future of food safety aims to prioritize water, energy, and chemical use in addition to pathogen reduction.

The Elite 360® was designed to meet those food safety and sustainability initiatives while protecting a protein processor’s bottom line. Diversey is here to help you assess your current processes and determine the chemistries and equipment right for your facility.

Download our free e-book for more details about the system’s development or visit www.birkocorp.com/elite360 to learn more about the innovative system.

Looking for a custom-made solution? Contact our team today.