2013 promises to be an interesting and challenging year for the meat industry. With the USDA Food Safety and Inspection Service (FSIS) focusing increasing attention on further processors and non-intact products we are receiving an increasing number of calls from small and small- to medium-sized processors asking about antimicrobial interventions. In many cases the callers are so overwhelmed by information that they are unable to make a decision on which product to use. This blog discusses some of the practical considerations that may be helpful as a processor selects an antimicrobial intervention or interventions in the further processing environment.

As a supplier of intervention products we recognize that there is no “one size fits all” intervention product and these suggestions are based on Birko’s experience in helping customers make these choices.

Interventions are a tool to control the food safety risks associated with your product. Interventions are required from good business and regulatory standpoints. The challenge is to select and implement interventions to control the food safety risk while at the same time controlling other risks. It’s also important to gauge how far to take an intervention program before it becomes unwieldy or unprofitable.

Another important consideration is efficacy. Obviously any intervention that is implemented by a beef processor needs to be effective at controlling E. coli O157:H7 and the non O157 STECs. While this is a key selection criterion, it is not the only factor that needs to be considered.

A suggested first step is to ask lots of questions: What type of product(s) am I treating – sub primals for portion cut steaks or incoming trim going to a grind or sausage mix? How much am I treating per day/per shift? Does the product ship fresh or frozen? What are the risks associated with my product and what are my target organisms: E. coli, Listeria, Salmonella or Campylobacter?

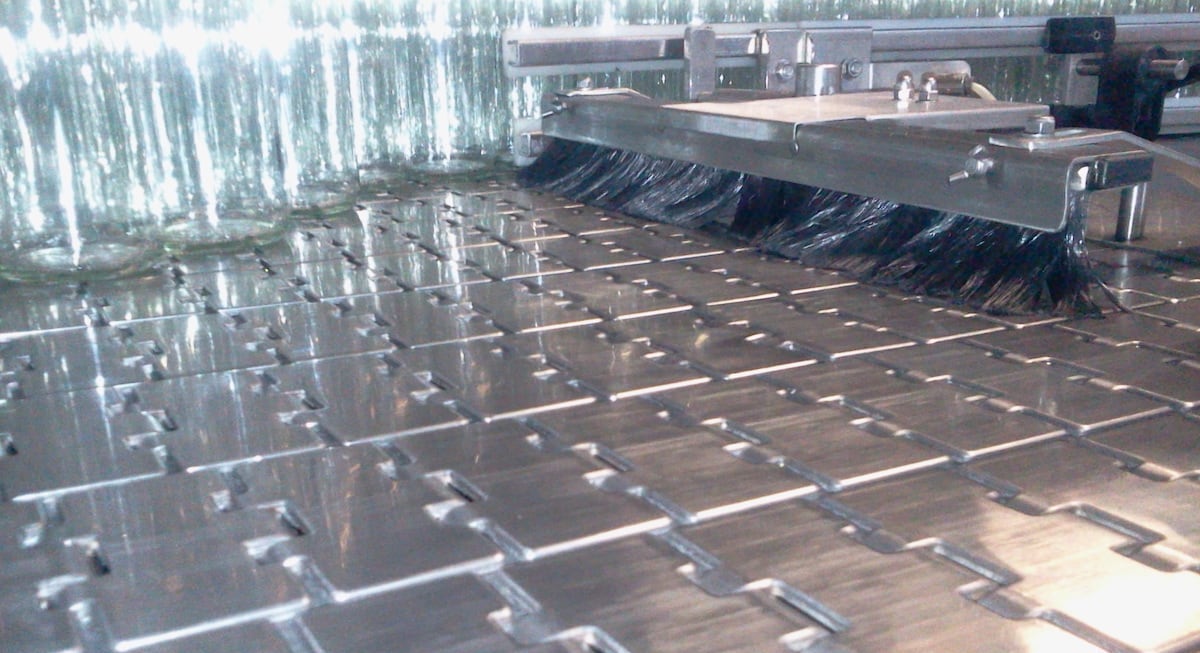

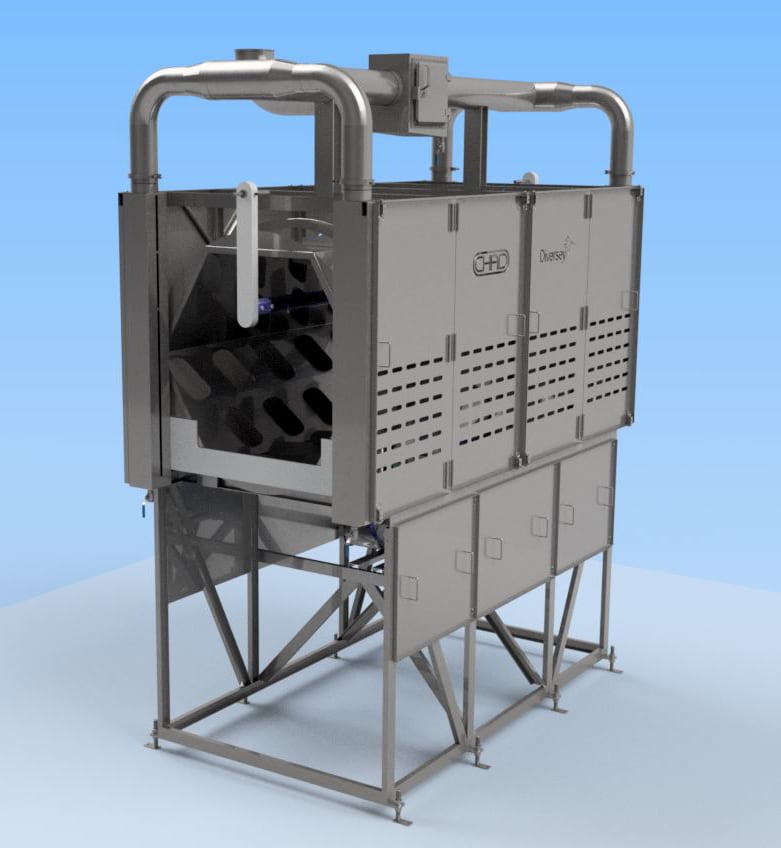

You should also ask how the product will be mixed and whether it needs a special activation process or activation system. How will I apply the product – do I need new equipment and how will this impact my current process? Birko’s equipment division, Chad Equipment, LLC, can help here. What other impacts will the intervention have on my plant and my employees? Will it corrode concrete floors, will I need additional ventilation and are there safety concerns surrounding its use? How will it impact my wastewater?

Is the intervention approved by the FSIS and is it listed in Directive 7120.1. or will I need to obtain a Letter of No Objection in order to use it in my application? Are there scientific studies available to support it use in my HACCP plan, and how is it going it to impact my label?

Finally, what is the cost of implementing the intervention, including not only the cost of the chemical product, but also the cost of equipment required for implementation. Some interventions are more costly than others to implement and operate. The impact on future plant maintenance costs can also be variable and should be factored in to the decision making process.

Before you implement a new intervention step we encourage you to take the time to fully consider all of the impacts that this is going to have on your product, your process and your facility.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.