Epic drought conditions have swept across the American West, threatening municipal supplies of potable water and causing severe conservation measures. Water is a more precious commodity than ever, especially for protein processing. In the face of this challenge, what can our industry do to save water and control costs?

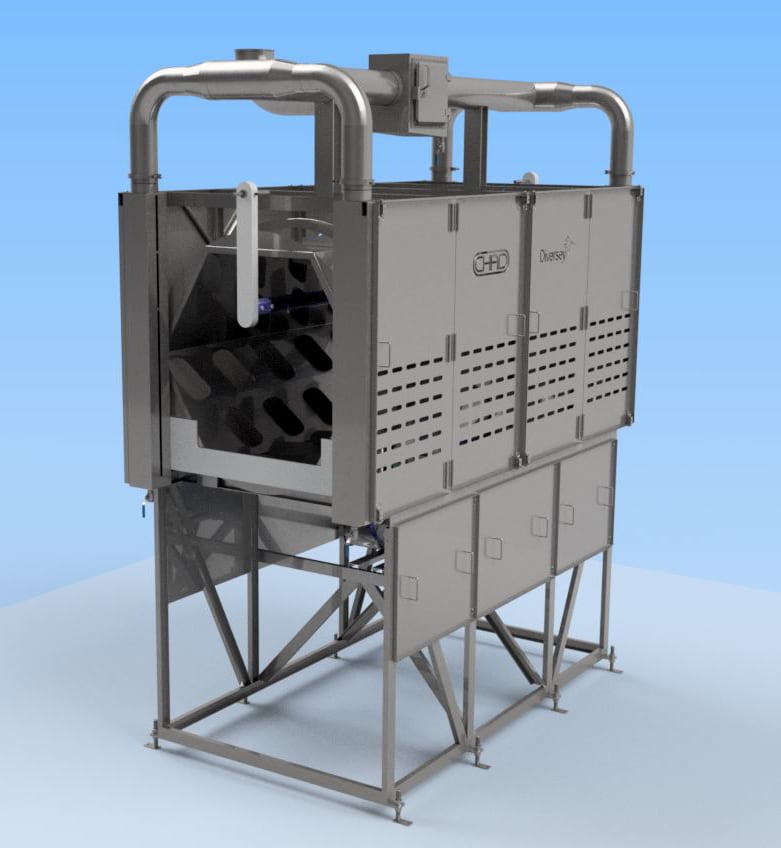

Chad Equipment, LLC, has been creating cutting edge harvesting and processing technology for over 30 years. Our patented recirculated hot water pasteurization system cut water usage by up to 90%.

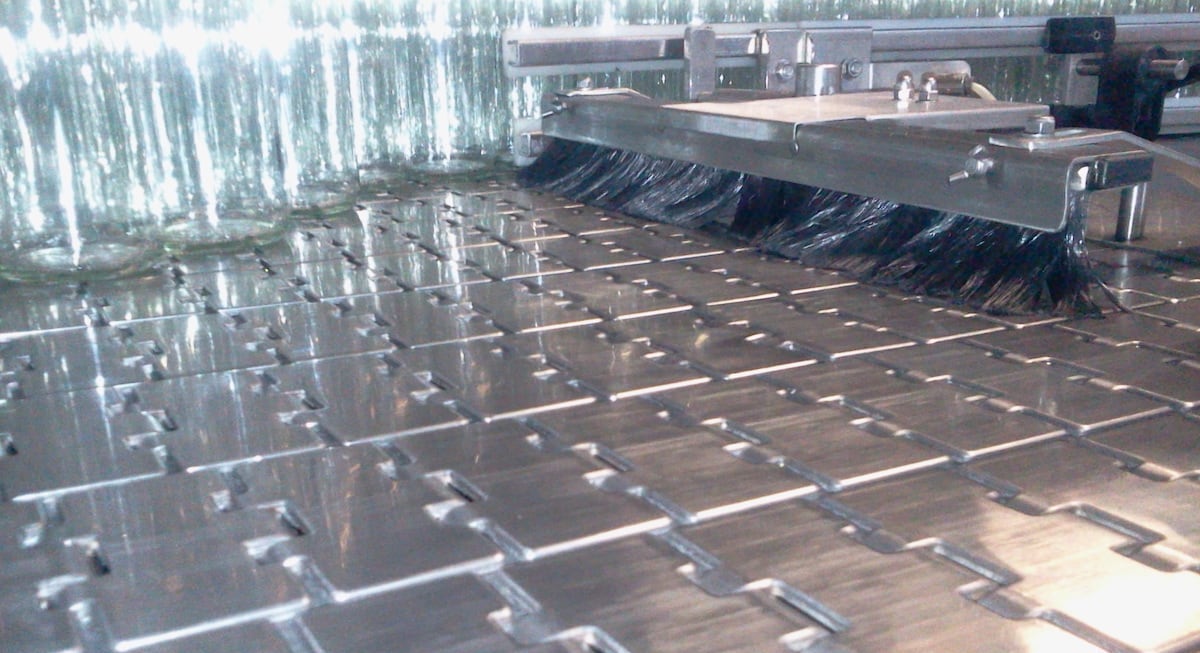

We recently introduced the patent-pending WaterSmart, which dramatically reduces water usage in carcass, head and tripe wash cabinets. In controlled tests conducted by Chad, WaterSmart reduced water consumption 30% to 40%.

For a two-shift, large plant operating carcass wash/bone dust removal cabinets six days a week, there are substantial water savings available through WaterSmart. Assuming 250 GPM at a cost of $7.00 for 1,000 gallons, here’s the cost for a conventional carcass wash:

15,000 gallons/hour = $105/hour

240,000 gallons/day = $1,680/day

1,440,000 gallons/week = $10,080/week

74,880,000 gallons/year = $524,160/year

However, the annual savings are substantial with WaterSmart:

At 30% reduced water consumption:

Hourly savings = $31.50

Daily savings = $504

Weekly savings = $3,024

Yearly savings = $157,248

At 40% reduced water consumption:

Hourly savings = $42

Daily savings = $672

Weekly savings = $4,032

Yearly savings = $209,664

This is clearly a sustainable and profitable advantage for processors.