Don’t waste your time trying to figure out which one came first. The bottom line is that eggs come from chickens, and eggshells can be contaminated with things such as fecal matter, blood, insects, and other soils.

That contamination can be off-putting for the consumer and may lead to outbreaks of salmonella and other foodborne illnesses. In order to protect the public from food safety risks, poultry processors need to clean eggshells.

Birko is excited to announce the launch of a new product – Egg-Shellent – a one-step egg washing compound that supports food safety for egg producers and processors.

It isn’t exactly a new area for Birko. The company served egg processing facilities back in its earlier days, and we’re eager to do so again. This new formulation allows us to do more to support food safety for poultry and egg product producers. Our team of expert food safety chemists and microbiologists worked to refine the product, optimizing the formulation for efficacy and safety.

Changes in Egg Processing Regulations

Earlier this year, the USDA and the Food Safety Inspection Service (FSIS) announced plans to modernize the way egg inspections are conducted. It’s the first time these methods were updated since congress passed the Egg Products Inspection Act in 1970.

FSIS Administrator Paul Kiecker said the changes are meant to bring egg plants in line with meat and poultry processing guidelines:

“Requiring egg product plants to develop food safety systems and procedures similar to meat and poultry requirements is a significant milestone in modernizing our inspection system.”

The chief change is that egg processors must have a standardized Hazzard Assessment Critical Control Plan (HACCP) in place. The HACCP system gives egg processors the flexibility to develop documented procedures that are tailored to specific plants and products.

FSIS is also taking over regulatory authority of egg substitutes and freeze-dried products – both of which present food safety risks when eggshells contain potentially harmful pathogens.

Yet another change in regulations is the fact that egg washing compounds no longer need USDA pre-approval before entering the market. While all these updates do give processors more flexibility and control over how food safety is handled, it also means more responsibility rests on their shoulders.

Egg processing facilities need to know the egg cleanser they’re using is an effective solution. With the average cost of a product recall averaging $10 million, choosing an egg washing compound that may fail to do its job is too large of a risk to take.

More About Egg-Shellent

Egg-Shellent from Birko is formulated using generally recognized as safe (GRAS) ingredients. Our in-house scientists in the R&D department conducted extensive laboratory testing on soiled eggs to ensure the compound’s efficacy.

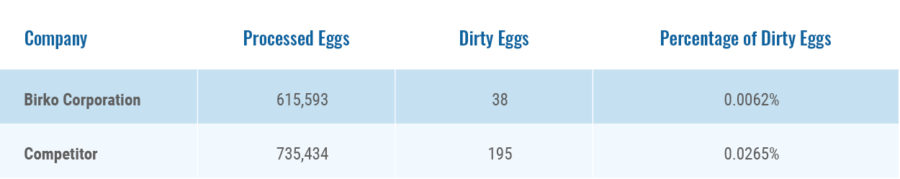

Birko also carried out field validation for Egg-Shellent, and here’s what the test revealed about the product.

The Egg-Shellent solution resulted in a 4-fold decrease in the number of dirty conventional eggs and more effectively controlled wash tank foam compared to the competing solution.

Birko Senior Formulation Chemist Brad Bray points out that there are two steps involved in egg washing: cleaning and sanitation. Egg-Shellent was developed for the cleaning process.

“First you clean eggs, then you sanitize,” he explains. “During washing, you usually don’t measure microbial load reduction. That’s more of a concern at the sanitizing step.”

Egg-Shellent’s formulation removes soils from shells so they can be properly sanitized before further processing.

Beyond Egg Washing: How Birko Can Help

Birko’s reputation in food safety precedes itself. As you make decisions about the right egg washing compound for your facility, you can have peace of mind knowing that our formulation is based on solid science and extensive testing.

As a food safety partner, Birko provides much more than just Egg-Shellent.

If you aim to implement more automation at your facility, the Birko by Lagafors suite of automated sanitation equipment offers solutions for plans of all types and sizes. This equipment has helped reduce both the need for labor and the amount of water used in plant sanitation.

Find out more about how sanitation automation addresses the issues of labor, energy conservation, and proper chemical usage in our free eBook on food processor’s biggest challenges.

As food manufacturing facilities look to address employee health and safety during the COVID-19 pandemic and beyond, Birko can help. Our Mobile Mister is a semi-automated portable sanitation system designed to eliminate pathogens on surfaces. It lets staff quickly sanitize common areas where employees congregate and fits through narrow spaces, ultimately reducing the spread of viruses in your building.

Birko’s experts are even available as consultants to help food processors develop effective HACCP plans. As the burden of responsibility to document unique food safety strategies falls to the egg processors, Birko can evaluate your facility, product, and current operations and find ways to improve sanitary design.