Since the passage of the Food Safety Modernization Act (FSMA) in 2011 and its implementation, the food processing industry has been tasked with navigating and meeting these new regulations. Produce and fresh cut processors in particular faced new challenges following the imposition of the FSMA rules, as they were not previously subject to the same level of regulation as the protein processing industry, forcing them to put new practices in place.

Along with meeting FSMA compliance, most of the recent outbreaks of foodborne illness have been connected to ready-to-eat produce items such as fresh cut leafy greens—products that are generally seen as healthy. Not to mention the pressure to prevent COVID-19 outbreaks in processing plants and consumers’ heightened attention to health and food safety.

All of this means produce processors in today’s economy have no shortage of food safety risks to mitigate. So, how can you stay ahead of the risk and ramp up food safety and sanitation at your plant?

Read on for tips and information on the latest innovations in produce chemistries and equipment.

1. Choose Food Safety Partners with Experience in Produce and Fresh Cut

Prior to the FSMA, produce processors weren’t required to follow the Hazard Analysis and Critical Control (HACCP) standards required for meat, seafood and juice products. Now, most produce and fresh cut processors who fall under the FSMA must develop and implement a Hazard Analysis and Risk-Based Preventive Controls (HARPC) plan, which is similar to a HACCP program. These relatively new changes, coupled with the heightened focus on food safety for produce, have birthed confusion about how to implement stronger sanitation methods in a way that works for both the product and the environment in which its processed.

That’s where your food safety partner can come in. Look for a food safety provider with expertise in working with produce and fresh cut processors and that’s well-versed in FSMA regulations. Seek out food safety partners who’ve gone through FSMA training, hold SQF and BRC certifications and have the depth of knowledge needed for effective sanitation in food processing.

Better yet, choose a reputable food safety partner who can help you evaluate what your unique concerns are and what solutions will work most effectively in your plant. There’s no one-size-fits-all solution to food safety in produce and fresh cut processing, so you’ll want to select a food safety partner that understands how to enhance your sanitation without damaging your equipment and that can provide the training and support necessary for using chemicals safely and effectively. It’s also important to choose a partner that can help you audit your processes, equipment and environment to help you stop product contamination in its tracks.

2. Add an Extra Level of Protection in Every Zone of Your Plant

Although there’s growing concern about product contamination and plenty of places for bacteria and pathogens to hide in your plant, there are also a number of industry players revolutionizing the ways we fight them. Novālent®, for example, has created treating and coating technologies that can have residual antimicrobial activity for up to 90 days without getting stripped off the equipment when cleaned (a downfall of other coatings on the market).

What is Novālent®?

Novālent® provides an additional hurdle that helps reduce the opportunities for environmental microbes to contaminate your product—it’s an extra layer of protection to stop surfaces from becoming a vector of cross-contamination. If you’re processing leafy greens, for example, on a surface contaminated with Listeria and transferred that lettuce to another surface coated with Novālent, the Listeria would be killed and unable to contaminate other lettuce products that follow.

Novālent can be applied to any clean, dry surface, including in break rooms, restrooms, locker rooms, tables or even harvesting equipment. This added layer of protection is particularly important, as unlike meat products, there are no intervention chemistries applied directly to the surface of produce to kill micro-organisms or a kill step such as cooking before the product reaches the consumer’s plate. As a result, you have to devote all the more attention to ensuring your product won’t pick up microbes on direct contact surfaces or as a result of cross-contamination from other zones in your plant.

How Novālent Works

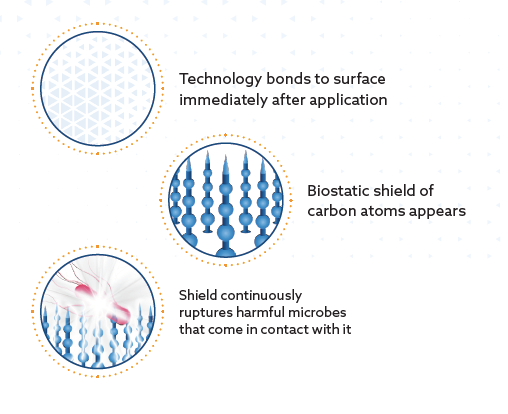

After deep cleaning and disinfecting a facility using Sterilex®, Decon7 or similar products, food processors can apply Novālent® AM RTU to direct food contact or adjacent surfaces to inhibit the growth of bacteria including Listeria, and other harmful bacteria and fungi. Once the coating has dried and bonded to the surface, it can have residual antimicrobial activity for up to 90 days. Since Novālent® forms a covalent bond with surfaces, it provides a protective layer of positively charged molecules that attract harmful organisms and destroy them.

Novālent® is not only promising for use on direct contact surfaces. In Zones 2 and 3, for example, it will prevent microbial colonization and the build-up of biofilms that could shed organisms that could potentially reach direct contact surfaces. It may even have potential to protect hoppers, knife blades and harvesting equipment beyond food processing plants. At Birko, we’re confident that Novālent® will provide a much-needed additional hurdle of protection in produce plants and peace of mind for processors, which is why we chose to partner with Novālent® and bring these groundbreaking solutions to our customers. Learn more about our partnership.

3. Consider Automated Sanitation

Finally, locating processes and tasks you can automate helps remove human error and can help save on water and chemical use. With automated solutions like Birko by Lagafors® Centralized Cleaning System, you can trust you’re getting the right dilution of chemicals, dispensed at the right time and with controlled water pressure. You get a consistent, reliable outcome, with automatic monitoring and documentation. That means you can elevate the food safety in your plant without requiring more labor or worrying about “pencil-whipping” in the documentation stage, all while saving up to 35% on sanitation costs and overcoming labor challenges. Learn more about how automation can help you save.

Stay Informed on Produce Sanitation Best Practices and Innovations

Keeping up to date on how you can meet the changing sanitation requirements for produce and fresh cut processing is the best place to start when you’re looking to optimize your processes. Consult your partner in food safety for its take on how you can meet FSMA requirements while protecting the food chain and reducing costs.

Learn More about Enhancing Sanitation in Your Food Processing Plant

Check out the webinar below on improving sanitation in ready-to-eat food processing, follow our blog for additional insights or get in touch with Birko for help in creating a process custom to your facility.