Meat shortages. COVID-19 outbreaks in meat processing plants. Backups in the supply chain. These are the stories that are dominating the news, and the major challenges every meat processor is trying to meet head-on—especially with consumers’ increased attention to food safety.

But, as the supply chain is seeing backups because of COVID-19, there’s another trend you’ll want to get ahead of as you address these unique circumstances: increases in steer carcass weights.

Now more than ever, we are seeing heavier steer carcass weights, which, while presenting opportunities for addressing food shortages, could also pose challenges for beef processors in regard to sanitation and food safety.

Here’s what you should know about the trend—and how you can be prepared.

Understanding Changes to Steer Carcass Weights

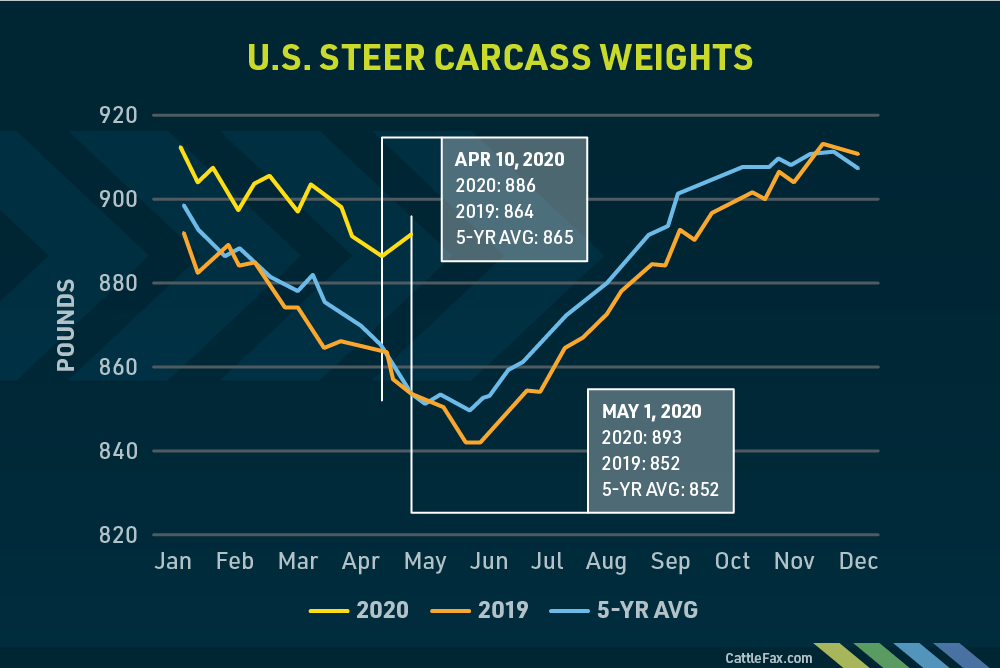

Cattlefax recently released data based on USDA findings showing that steer carcasses are getting significantly heavier. As of May 1, 2020, U.S. steer carcasses weighed 893 lbs compared to 852 on the same day in 2019—a 41-lb difference.

Compared to carcass weights over the last five years, beef carcasses weigh 34 lbs more on average, and in just three weeks (April 10-May 1, 2020) jumped from 886 lbs to 893 lbs.

These increases are almost certainly the result of cattle on feed longer than usual because of decreases in harvesting. We can expect this trend to continue, at the very least until normal beef harvesting processes resume.

Opportunities for Addressing Beef Shortages

With heavier carcasses, we can also naturally expect more trim as the beef is processed, which has upsides for both beef producers and consumers. As of May 11, beef production is down nearly 31% compared to 2019, according to the USDA. Yet, as consumers are cooking more at home and are concerned about potential meat shortages, meat sales have gone up. In March, beef sales were $158 million higher than the comparable week in 2019. 55% of those sales came from ground beef. The trend is likely to continue, and some grocery stores are beginning to instill limits on meat purchases to curb shortages.

Excess trim from heavier carcasses may offer a solution to some of these challenges. Since the onset of the COVID-19 crisis in the U.S., ground beef has been one of the most sought-after products for its versatility and relatively easy prep. In fact, in March, ground beef sales increased by 52%. Ideally, as steer carcass weights go up, meat processors can use the larger amount of trim to produce more ground beef and meet increased consumer demand as beef slaughter continues to slow.

Challenges for Processors

Despite the potential for addressing ground beef shortages, processing heavier steer carcasses won’t come without challenges. Sanitation and food safety practices are under more scrutiny than ever before as consumers have heightened concern about the spread of COVID-19. And, as consumers buy larger amounts of ground beef, it’s crucial that those products are treated properly. Beef processors simply can’t afford product recalls or food safety issues—especially with ground beef—at this time.

Ramping Up Sanitation Practices

Using effective sanitation solutions, disinfecting production areas and taking additional measures to protect your employees against COVID-19 are all important efforts in ensuring your plant remains safe and open. But, you’ll also want to evaluate your product sanitation and decontamination methods to determine ways to ramp up food safety with minimal disruption to your processes.

That’s where your equipment comes in. With the right technology, you can get better coverage of antimicrobials on your products—and significantly reduce the risk of pathogens.

Using Electrostatic Intervention Technology for Eliminating Pathogens

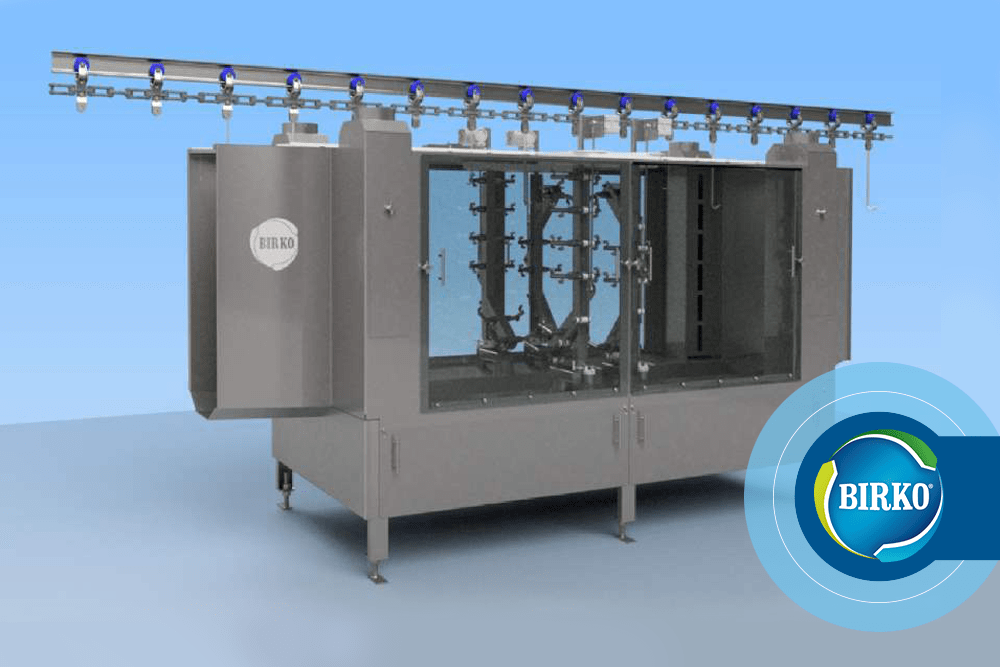

Emerging electrostatic technology is a game-changer when it comes to sanitizing meat products, and Birko has been able to harness it with the Elite 360® and Head and Tongue Wash offerings. Birko’s Elite 360® precision application technology uses electrostatics to apply antimicrobials to trim prior to grind and achieves 360-degree coverage, reducing pathogens and utilizing chemicals more efficiently than traditional sanitation methods. Here’s how it works:

Equipment like Elite 360® will be pivotal in processing higher amounts of trim that come with heavier steer carcasses and creating peace of mind that ground beef leaving your facility is pathogen-free.

Offsetting Sanitation Costs and Creating Efficiencies

As a food safety partner for meat production facilities, we’ve seen a dramatic increase in meat processors reaching out to us for sanitation solutions and equipment, disinfectants and handwashing solutions as they grapple with bolstering sanitation at their plants.

With higher absenteeism—some plants experiencing 30% or more —and slowed production, wasted chemicals, water and resources become an even heavier blow to your bottom line than in normal circumstances. It’s a perfect storm that might have you feeling like you can’t keep your head above water.

That’s why it’s especially important to locate ways you can save on resources and create efficiencies where you can. In addition to minimizing the risk of pathogens on beef trim, our Elite 360® precision application technology reduces the amount of chemicals used and therefore wastewater needing treatment. When compared to conventional dip tank methods in poultry production, for example, electrostatic technology can reduce chemical and water use by up to 95%. As you’re utilizing higher amounts of disinfectant and sanitizers than usual, conserving chemicals used on product surfaces is a major way to offset cost.

Our Head and Tongue Wash provides a way to conserve water—and importantly, labor. Our head and tongue wash can save 1-2 laborers per shift, meaning you can reallocate those laborers to other areas of your plant and save up to $100,000 per shift annually on labor costs. In a time where we’re seeing such high absenteeism rates and are adjusting practices to accommodate for social distancing, the Head and Tongue Wash provides a viable solution for making up for labor shortages. And, electrostatic intervention technology is also available with this product for ultra-efficient pathogen prevention and food safety. Learn more about it in this video.

Consult Your Partners in Food Safety

With food safety and COVID-19 prevention currently at the forefront of all meat processing discussions, it can be hard to know where to start. With over 65 years of experience in food sanitation, Birko is here for your sanitation needs, whether you need advice on how to move forward under increased scrutiny for food safety or would like to learn about how the Elite 360® can help you accommodate higher amounts of beef trim at your facility.

View our resources on COVID-19 or contact us to learn more about steer carcass weight trends and how we can help you get ahead of food safety challenges during this time.