Proper cleaning in the brewery is the single most crucial thing brewers can do to ensure good quality, great tasting beer, time after time. Caustic (NaOH or KOH) has been the primary chemical of choice in breweries to remove protein soil from the brewhouse to packaging and everything in between for decades. With its high pH (>12) at 2-3% active caustic, sodium hydroxide or potassium hydroxide is very effective at hydrolyzing (breaking down) soil.

Caustic Cleaning Concerns

Without additional additives such as surfactants, chelators, water conditioners, and rinse aids; however, caustic used alone can promote beerstone deposits and leave and unsanitary surfaces. Nowadays, the so-called “built” caustics with the aforementioned additives can significantly reduce the amount of chemical required to clean the surface and reduce or eliminate the need for an acid neutralization step after the cleaning.

CIP Cleaning is a Superior Solution

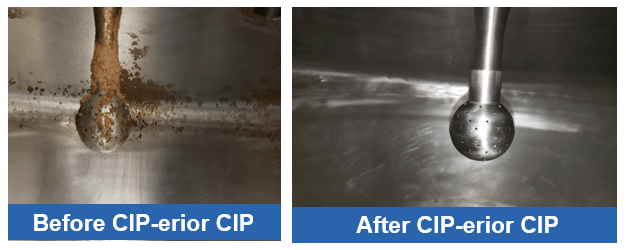

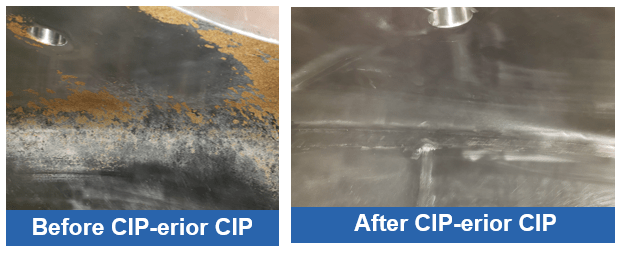

Birko’s new CIP-erior Liquid Caustic CIP is just such a product. Designed especially for brewery CIP, CIP-erior utilizes the latest and greatest advances in surfactants, chelation, dispersants (polymers), and rinse aids to provide excellent cleaning while requiring less chemical to do the job, and reduces the need for an acid finish afterward.

Don’t take my word for it – see the superior results for yourself!

If you need additional assistance regarding CIP cleaning or overall best practices for brewery sanitation, contact Birko today.