The “Internet of Things” is here and amazing advances are not far behind.

Many devices and heavy equipment which were formerly unable to communicate will soon be sharing information and collecting data. This networking technology represents great opportunities for the food industry.

Information including temperature, pressure, flow and acoustics can be captured and sent to higher platforms for dissemination. The analytics can be handled on site or off site. Patterns can be discerned and action taken to stop an incident before it happens. For example, if a sensor on a motor detects a steady uptick in temperature a technician can be automatically notified to service the motor before it fails. Actionable information can be provided to the right person at the right time. No downtime…no lost production.

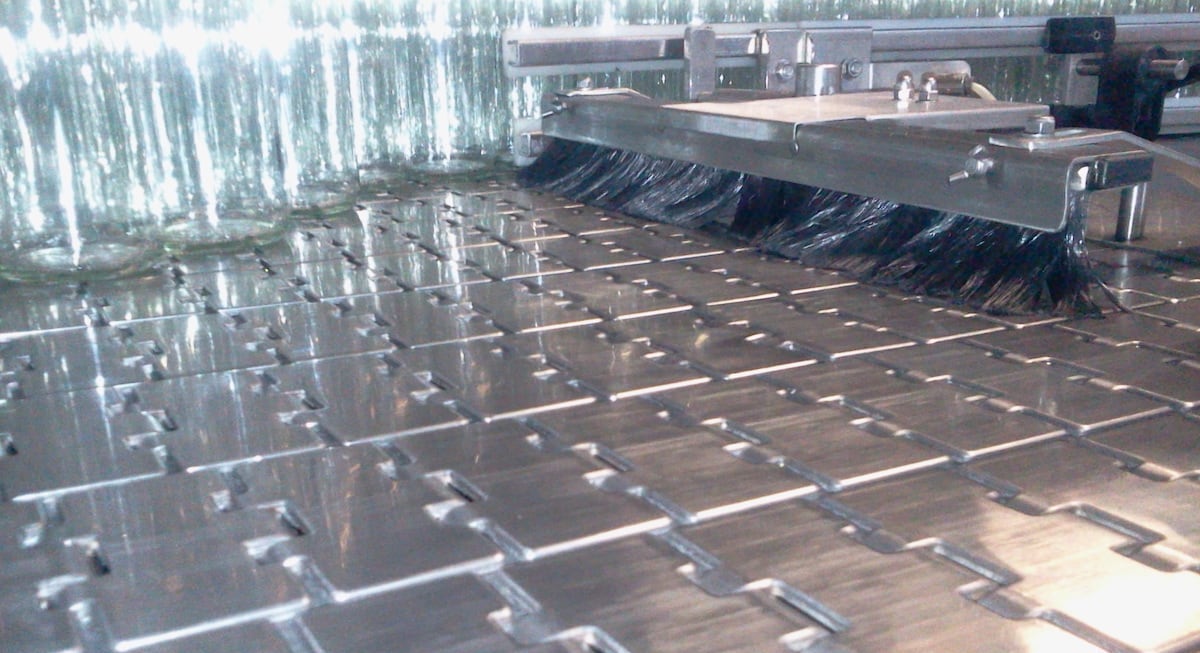

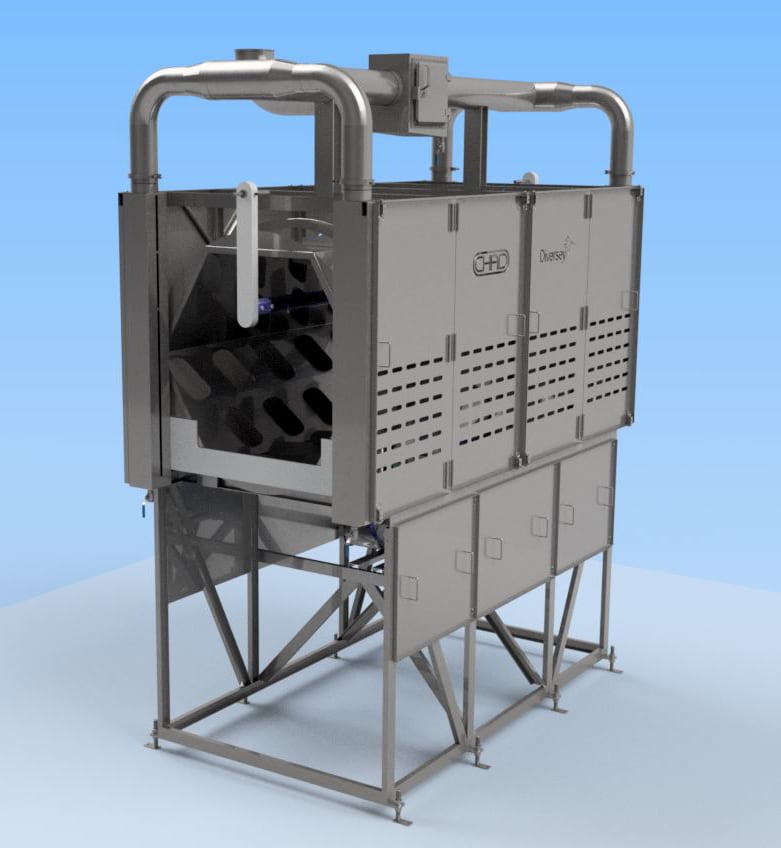

Chad Equipment is taking advantage of this technology and incorporating it into our equipment portfolio. Integrating communication and gathering useful data is at the heart of our WaterSmart system. WaterSmart is a patent pending technology that will guarantee 30-to-40% reduction in water and chemical use. Tracking this information is vital to the success of WaterSmart.

Another potential benefit of networking technology on WaterSmart involves nozzles that wear over time. As nozzles wear, the nozzle orifice becomes distorted and allows more water to pass through the system. Water consumption creeps up. The WaterSmart system allows a pre-determined maximum level of water consumption to be set. When that level is breached an alert can be sent. The Chad technician will be contacted to perform a service visit and replace nozzles.

The “Internet of Things” is making food industry equipment intelligent. Equipment systems will be able to communicate with each other and plant personnel. The future of food industry equipment is very exciting.