One of the major news stories this summer is the drought across the Midwestern and Great Plains states. Although the drought is especially severe this year, some parts of the country such as the Southeast and Texas Panhandle have been in a drought situation for several years.

Water is an essential component of almost all food and beverage processing operations, either as an ingredient in whatever is being produced or is used for cleaning and sanitation, or other food safety practices. There are a number of simple strategies that producers can employ to reduce their water consumption. Self-audits of water use can be a simple and effective way to identify where water is being used and potentially wasted in your facility, and in many instances minimal cost fixes can be implemented to reduce the volume of fresh water needed.

Start by looking for and repairing the obvious. Items such as dripping or running faucets, leaking toilets, carcass or other wash cabinets left running during production breaks or other line downtime can waste a tremendous amount of water. The next step involves examination of water use practices. For example, consider whether wash down hoses are being used in place of other clean-up methods such as scrapers or squeegees. Are water flows to knife and tool sterilizers greater than they need to be, and are they left running during breaks? Another consideration is whether you have optimized the water use at the carcass wash or other similar cabinets. I have been in plants where a cabinet had an operating parameter range of 105 – 220gpm, and was being run at 210gpm because that was the way it had always been. A little testing showed that the cabinet functioned just as effectively at 140gpm, which was an instant savings of 30% or 12 gallons per head at a 5,500 head a day operation. This adds up quickly – this no-cost fix had the potential to save 67,000 gallons per day or over 13 million gallons per year.

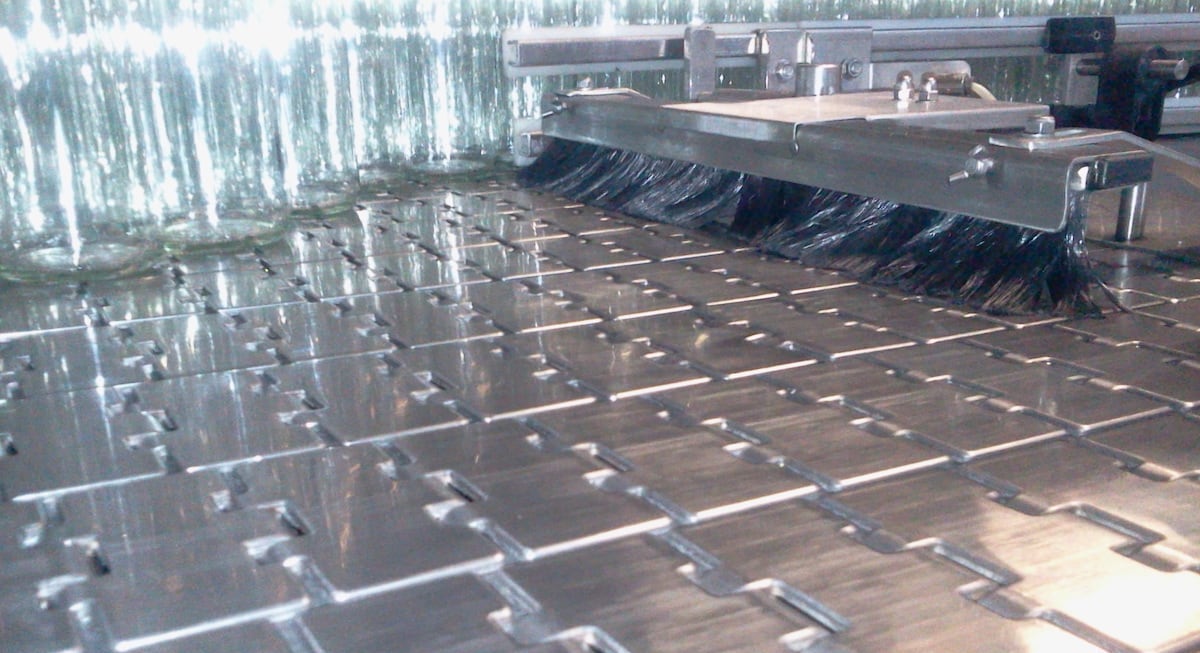

Other options to consider are whether there is a way to reuse water from one process elsewhere in a way that doesn’t jeopardize food safety. Some breweries capture the water that is used to rinse the empty bottles before filling and reuse it to wash the foam off the filled and capped bottles before labeling. Another brewery took the water that was used to back flush the sheet filter and used it for the pre-CIP rinse on the fermentation tanks.

Cleaning and sanitation is another area where water savings can be implemented relatively simply. Completing dry pick up properly before starting to wash down is a huge saver of water – I have been in many plants where a wash down hose took the place of shovel and squeegee, wasting gallons of water. Similarly when washing down and rinsing, a systematic method of top to bottom, moving from the periphery of the room toward the center will speed the process and save water. CIP operations can also be evaluated for potential savings – can the CIP be accomplished with 500 gallons instead of 600 gallons? Make sure your sanitation crew optimizes the volume of water used. Several short sharp burst rinses can be just as effective as a prolonged continuous rinse, especially when combined with the use of pH strips to determine when rinsing is complete. Timing water flows using a stopwatch is an easy way to monitor and control use.

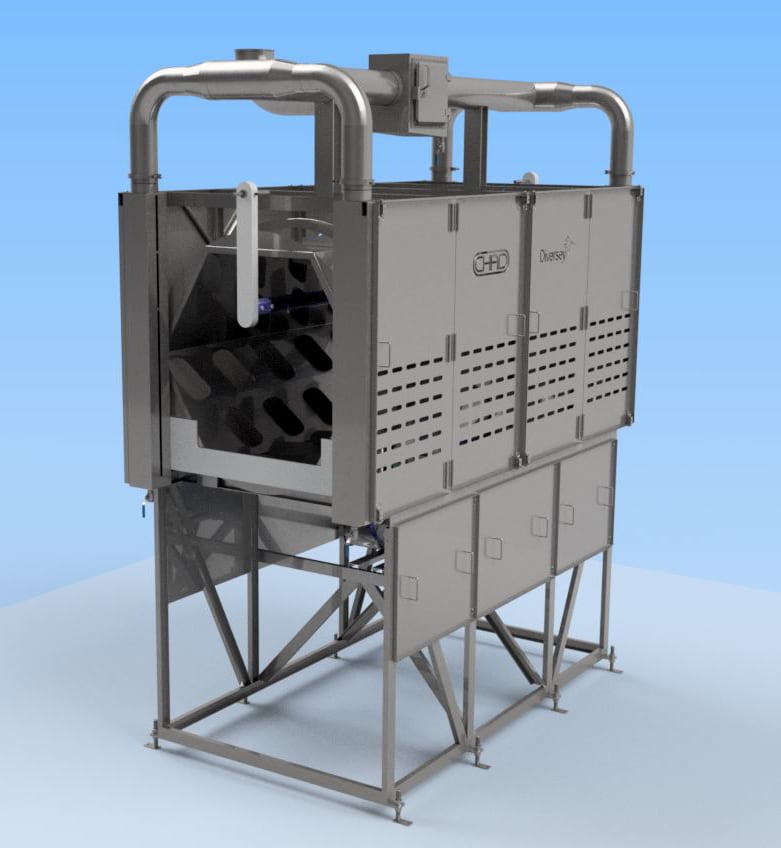

Finally, there are the longer-term options that will require capital expenditure and therefore longer planning but can still be way to save water. Single water use carcass wash cabinets can be converted to or replaced by cabinets and equipment designed to allow the reuse or recycling of water. Effluent from bone dust or similar carcass cabinets can be collected, filtered and reused in hide-on washes. Away from the processing floor, options such as waterless urinals and other water saving measures can be installed.

While the drought will eventually break, one thing is certain, water will become an increasingly scarce and valuable resource. Food processors owe it to their communities to be wise water stewards.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.

Elis Owens, Ph.D., Director, Technical Services, Birko, can be reached at [email protected], 303-289-1090.